Coadiuvanti per la lavorazione dei minerali

Ottimizzazione delle operazioni di lavorazione dei minerali

Nalco Water è leader mondiale nella produzione di reagenti e soluzioni per la lavorazione dei minerali. Abbiamo decenni di esperienza in una vasta gamma di mercati e più di 1.600 collaboratori globali in ricerca, sviluppo e ingegneria. La nostra portata globale e la nostra competenza ci aiutano a offrire soluzioni tecniche, economiche e sostenibili dal punto di vista ambientale per la lavorazione dei minerali, dalla miniera allo stabilimento.

Il nostro portfolio diversificato di coadiuvanti per la lavorazione dei minerali copre una vasta gamma di applicazioni e comprende modificatori reologici, coadiuvanti di filtrazione, modificatori della crescita dei cristalli, stabilizzatori di liscivio, stabilizzatori di ossalato e reagenti per la rimozione degli umati. Aiutandoti a ottimizzare i processi industriali minerari, Nalco Water ti consente di aumentare al massimo la produttività, migliorare il rendimento e avere un impatto positivo sui profitti.

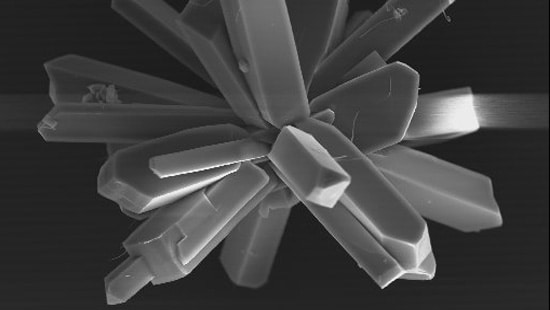

In primo piano: modificatori della crescita dei cristalli

Nell'ambiente competitivo della raffinazione dell'allumina, gli impianti

di lavorazione sono continuamente spinti ad aumentare il rendimento, mantenendo intatte le dimensioni e la qualità dei cristalli di idrato.

Nalco Water propone programmi di modificazione della crescita dei cristalli (CGM) ideati specificamente per l'uso nei circuiti di precipitazione dei processi industriali di Bayer. I programmi offrono un controllo aggiuntivo dei meccanismi di agglomerazione e nucleazione, i quali possono avere un impatto positivo sul controllo delle dimensioni del prodotto finale, sulla resa del liscivio, sulla classificazione dell'idrato e sul controllo dell'interferenza degli ossalati.

I CGM rappresentano solo uno degli innumerevoli coadiuvanti per la lavorazione dei minerali offerti da Nalco Water. Contattaci per parlare delle tue esigenze operative specifiche e per saperne di più sulle nostre soluzioni di lavorazione dei minerali.

Flotation 360™

L'ottimizzazione della lavorazione dei minerali può sembrare un bersaglio mobile. La sostituzione del minerale, una formulazione errata o il mancato bilanciamento tra recupero e qualità possono avere ripercussioni sui profitti. Ma Nalco Water ha la soluzione: Flotation 360. Questa tecnologia digitale ti aiuta a massimizzare la produttività e a ottimizzare le performance del tuo circuito di flottazione.

Ottimizza il tuo circuito con le capacità predittive di Flotation 360:

- Migliora le performance per aumentare il recupero e la redditività

- Migliora la visibilità dei potenziali impatti dei futuri cambiamenti del minerale, consentendo di mitigare in anticipo eventuali sfide

- Ottimizza il dosaggio dei reagenti e il consumo di prodotti chimici, migliorando il costo totale delle operazioni

- Riduci le sfide di manutenzione come guasti alle valvole delle celle di flottazione e dedica meno tempo alla risoluzione manuale dei problemi

Storie di successo sui coadiuvanti

per la lavorazione dei minerali

Il programma di modificatori della crescita dei cristalli offre miglioramenti in termini di efficienza, sostenibilità, performance e costi in uno stabilimento di allumina

In uno stabilimento di allumina del Mediterraneo, la responsabilità sociale aziendale ha svolto un ruolo importante nelle sue attività quotidiane. Con uno sguardo rivolto alla sicurezza, all'uso ottimale delle risorse e alla riduzione dei costi, lo stabilimento ha cercato metodi nuovi ed efficaci per migliorare l'efficienza totale dei processi industriali.

Nella sua collaborazione con lo stabilimento, Nalco Water ha compreso

che l'applicazione di un modificatore della crescita dei cristalli avrebbe potuto portare ai risultati di cui l'impianto aveva bisogno.

Scarica il case study per scoprire come il programma di modificatori della crescita dei cristalli di Nalco Water ha contribuito a generare un valore di oltre 743.000 euro all'anno in termini di maggiore redditività e risparmi.

Guidare l'innovazione nella lavorazione globale dei minerali

Nalco Water attribuisce una grande importanza a ricerca, sviluppo e innovazione. Nel nostro impegno per affrontare le sfide della lavorazione dei minerali, abbiamo riunito team dedicati di chimici e ingegneri per guidare i nostri centri di ricerca tecnica incentrati sul cliente in tutto il mondo. Dagli Stati Uniti all'Australia occidentale, dai Paesi Bassi all'India occidentale e ovunque nel mezzo, Nalco Water offre un team di esperti interconnessi a livello globale, che operano localmente nel tuo stabilimento e sono profondamente consapevoli delle sfide regionalizzate che possono avere un impatto sulle tue attività.

Coadiuvanti Nalco Water per la lavorazione dei minerali

Questo disperdente è una formulazione acquosa a basso peso molecolare, appositamente progettata per essere un efficace disperdente e antincrostante nelle applicazioni di lavorazione dei minerali in cui vengono utilizzati circuiti ad alto contenuto di calce. Il disperdente agisce riducendo la viscosità delle miscele minerali. Può anche modificare la formazione dei cristalli e quindi alterare la natura e la velocità di deposizione delle incrostazioni.

- Migliora la reologia dello slurry.

- Pulisce le superfici dei minerali favorendo il recupero di minerali preziosi.

- Riduce la velocità di deposizione del calcare laddove sono prevalenti problemi di incrostazione.

- Previene la formazione di patina viscida sui minerali preziosi.

- Proprietà non schiumogene.

- Stabile alle alte temperature.

| Prodotti |

|---|

| NALFLOTE 600-05 |

I coadiuvanti per la disidratazione Filtermax vengono utilizzati principalmente per agevolare la filtrazione di concentrati minerali, al fine di ridurre l'umidità del residuo di filtrazione e migliorarne le caratteristiche di gestione. Agiscono abbassando la tensione superficiale dell'acqua e, cosa più importante, rendendo le superfici delle particelle minerali più idrofobiche (idrorepellenti), consentendo così livelli maggiori di riduzione dell'umidità.

- La minore umidità del residuo riduce i costi di essiccazione e di trasporto.

- Velocità di filtrazione più elevate riducono l'investimento di capitale nei filtri.

- Il migliore rilascio del residuo aumenta l'efficienza dei filtri.

- La riduzione dell'effetto occlusivo del tessuto filtrante ne prolunga la durata.

| Prodotti |

|---|

| FILTERMAX 470LV |

| FILTERMAX 440GFM |

Programmi, prodotti, apparecchiature e servizi

Scopri le nostre soluzioni di coadiuvanti per la lavorazione dei minerali

Non è stato possibile trovare nessun risultato per "".